Life lessons come in all kinds of packages and often from unusual sources. Astute businessmen are quick to take lessons learned in other industries and apply them to their own operations. That’s why we’ve been talking this week about a three-year study of musculoskeletal injury risk factors in the trucking industry (see our April 27 and 29 posts). Any time workers are forced to work in uncomfortable positions for long periods of time or repeat uncomfortable actions over time, undue strain is placed on the body’s sensitive musculoskeletal system, increasing the risk of serious injury. The result is the same whether you drive a long-haul truck across country or spend your shift moving material back and forth across a factory floor. The trucking industry study only serves to remind us that material handling operators face the same physically-challenging, musculoskeletal risk factors, just in a different setting.

Musculoskeletal injuries in the workplace account for the greatest number of worker’s compensation claims in the U.S. each year, according to the U.S. Department of Labor, which places the annual price tag of such injuries at more than $60 billion. But the true cost of back injuries, tendonitis, carpal tunnel syndrome and other stress and repetitive motion injuries is far greater than the direct medical/insurance cost. Poorly designed material handling equipment that forces workers to stretch and strain decreases productivity, negatively impacts product quality, lowers morale, and increases absenteeism. The true annual price tag for workplace injury and illness is estimated in excess of $171 billion.

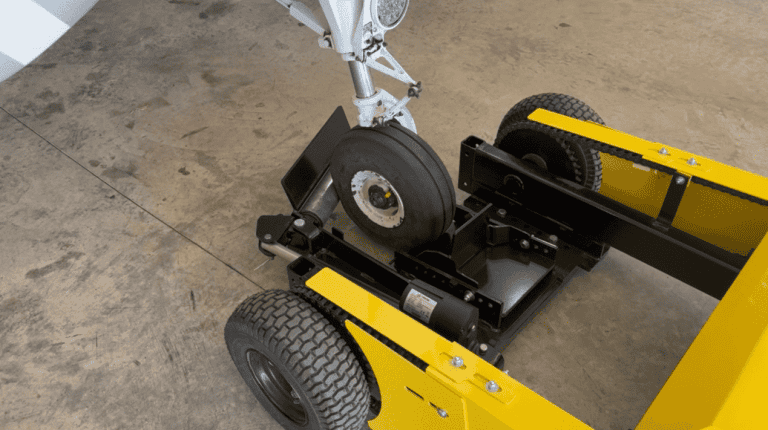

A national leader in the design and manufacture of ergonomic solutions to material handling applications, DJ Products specializes in making the finest, most versatile, electric and motorized cart tugs in the industry. Ergonomically designed to take the stress and strain off workers, our products have earned as many kudos from customers for their role in increasing production efficiency as they have for improving worker health and safety. Here are just some of the ergonomic design features that make DJ Products’ material handling equipment stand out from the competition:

- Exactingly-engineered ergonomic controls place operating controls at the precisely optimal position for easy use and maximum operator control while eliminating carpal tunnel injury.

- Versatile adjustable tug arms allow carts to securely attach to the bottom of any cart or load, even those loads that overflow the cart bed.

- Our scissors-lift option allows each worker to raise or lower materials to his personal, optimal work height.

- Safe, smooth 180-degree pivoting is ensured with our unique tug arm, eliminating the risk of dangerous jackknifing while maneuvering heavy loads.

- Energy-efficient electric battery-powered operation guarantees safe, quiet, green operation through two full shifts before recharging.