The U.S. auto industry is starting to make its comeback. The U.S. Department of Energy has awarded the first loans from the $25-billion Advanced Technology Vehicles Manufacturing Loan Program authorized by Congress to support the U.S. manufacture of energy-efficient cars and automotive components:

- Ford Motor Co. was granted $5.9 billion to retool factories in Illinois, Kentucky, Michigan, Missouri and Ohio to manufacture fuel-efficient vehicles.

- Nissan North America received $1.6 billion to retool its Smyrna, Tennessee manufacturing plant to produce electric vehicles.

- Tesla Motors got $465 million for production of advanced electric vehicles in California.

Other signs of industry recovery include Gestamp Corporation’s $90 million investment in a Chattanooga, Tennessee stamping operation to produce parts for Volkswagen’s new mid-sized sedan, and Ralco Industries’ $6.4 million expansion of its Pontiac, Michigan facility to increase production of welded assemblies for the auto industry.

It’s a relief to finally see the first twitch of life in the U.S. auto industry. And it’s exciting to see the industry retooling for what promises to be a robust future. But along with forward-thinking changes in their product line, the auto industry should be implementing innovation changes in their production practices. Retooling initiatives should include ergonomic material handling equipment on the assembly line, on plant floors and in factory storage lots to ensure the protection of workers’ health and safety. The workers who made concessions in pay and health benefits to keep the auto companies alive deserve to work in an environment that promotes good health. The citizens who provided the cash that the government is using to fund the loans that are jump-starting new life into the auto industry deserve to know that every possible measure is being taken to create a financially lean manufacturing operation. Ergonomic material handling equipment accomplishes both goals.

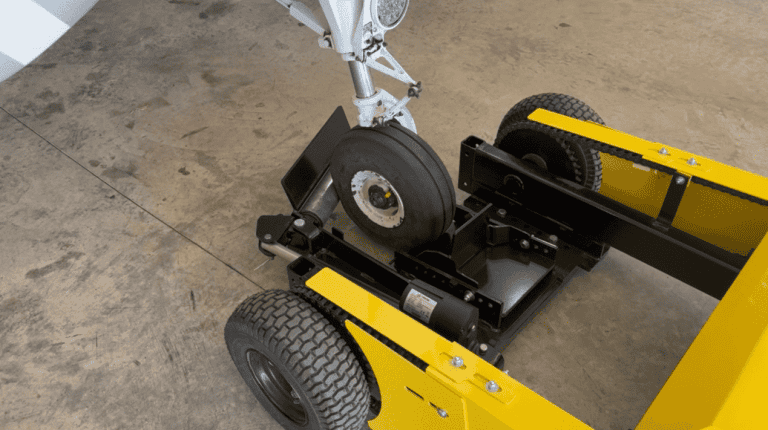

Ergonomic equipment like DJ Products’ CarCaddy car and vehicle pusher pushes heavy equipment down an assembly. The CartCaddyLH electric tug can push a vehicle down a rail or be used to push/pull from station to station heavy carts of raw materials or parts weighing 10,000 to 50,000 pounds. The DealerCaddy car and truck pusher easily maneuvers cars and trucks around storage and dealer lots. All DJ Products’ material handling carts and movers are ergonomically designed to prevent expensive and debilitating musculoskeletal injuries. Ergonomic equipment and practices have been proven to cut production time and costs, protect workers’ health and safety, improve worker morale, and significantly reduce the musculoskeletal injury expenses that cost U.S. businesses more than $150 billion each year. Including ergonomics in auto industry retooling efforts just makes sense — for the auto industry, for workers, and for taxpayers.